This technology from MACH gives you a machine with direct forward throw sweeping and a front driving position. This guarantees maximum performance in debris collection and maximum handling during operation.

MACH 8 - THE RIDE-ON SWEEPER, WITH DIRECT FORWARD THROW AND A FRONT DRIVING POSITION.

MACH 8

The MACH 8 is a powerful, heavy-duty sweeper, with a wide cleaning path (up to 2.310 mm / 89 in).

It is an extremely robust sweeper (both the machine’s chassis and body are made of steel) and is high performing even in the collection of large quantities of dust and gravel.

The superior features and dirt container capacity (up to 500 L / 132 gal) make the MACH 8 the perfect solution to quickly clean large areas that are extremely dusty or dirty, in any application, which includes demanding environments such as heavy industries.

The innovative design of the MACH 8 – the only machine on the market that offers direct forward throw sweeping and a driving position at the front of the machine with an automotive steering system – makes this industrial sweeper particularly maneuverable. This is a great advantage in contexts, where it is necessary to carry out cleaning not only quickly but with great precision, due to the presence of confined and congested spaces. For example, in logistics warehouses where goods are constantly being moved.

The MACH 8 is easy to drive, with a compact turning radius, it has the perfect dimensions to clean the corridors between one stock rack and another in modern logistics centers.

The highlight of the MACH 8 is its capability to pass over speed bumps and manage sudden changes in gradient. The new machine from MACH is in fact the only machine on its kind which offers a practical solution to this problem, an impossible task for any other industrial sweeper.

For this reason, and the fact that the MACH 8 can overcome gradients of 21% without losing power, the machine is well suited to clean large parking areas (open air, covered and multistory).

The dirt container (also known as the hopper), with rear hydraulic lift, is made completely in steel and has a capacity of 500 L / 132 gal. The high dump system (which lifts to a height of 1.580 mm / 62.2 in) effectively compacts debris, utilizing all the available space in the container, before having to stop operation to empty.

On the right side of the machine, which is key when cleaning along curbs and when making turns, there is not just one, but two side brushes therefore raising the standard of cleaning and avoiding the loss of debris during a curve (a phenomenon known as sweeper trailing). A left side brush is also available as an optional.

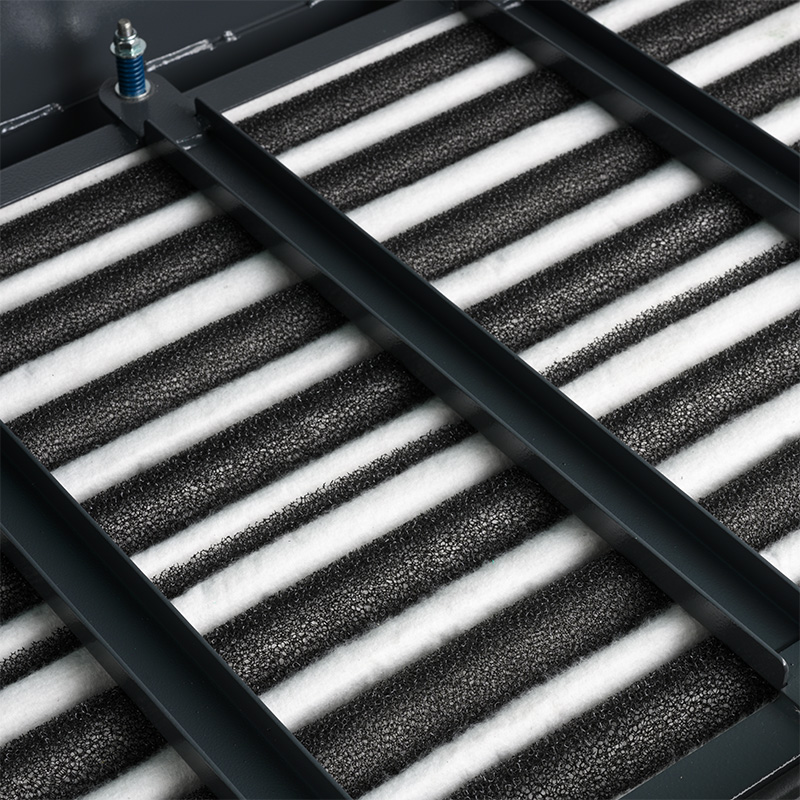

The MACH 8 is fitted with an antistatic filter, which is washable, with an automatic shaking system for the cleaning of the filter. The smart design of the filter (without tight corners) and its large dimensions, guarantee high filtering performance that is maintained over time.

A unique filter shaker automatically activates at the end of operation, in order to shake out dust residues from the filter. It is important to note that the vibrations that shake the filter are only transmitted to the material of the filter and not to the structure of the filter case. This is a fundamental detail which prevents wear of the casing and gaskets.

Mechanical drum brakes are oversized to eliminate electronic cards and over exertion by the operator/ Mechanical handbrake / Roll bar to protect operator’s neck / Seat belt / Automotive indicator lights / Seat pressure sensor / Reverse beeper / Flashing light…these are just some of the safety features used by MACH to guarantee maximum safety.

AVAILABLE VERSIONS

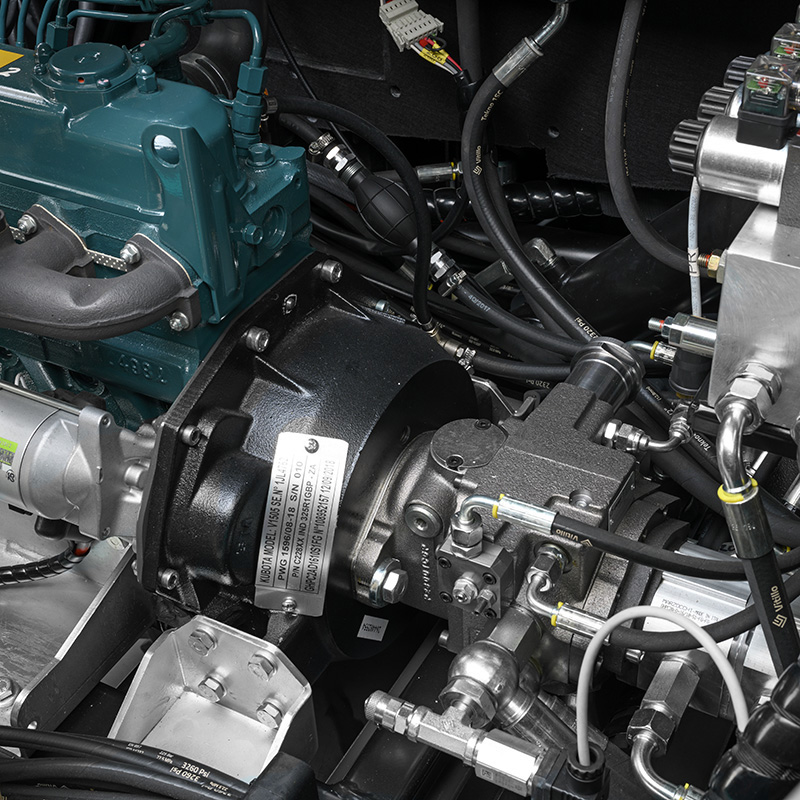

- MACH 8 HDK – with 1,500 cm3, 4-cylinder, 36 hp Kubota engine with liquid cooling.

- MACH 8 HGK LPG – with 1537 cm3, 4-cylinder, 42,6/44,8 Hp (Petrol / LPG) Kubota engine with liquid cooling.

APPLICATIONS

- INDUSTRIAL MANUFACTURING: Paper mills, cement works, glassworks, foundries, brickworks, sawmills, power plants, distilleries…

- LOGISTICS: warehouses, logistics hubs, food storage facilities, ports and airports, grain and seed stores, fruit and vegetable wholesale markets…

- PUBLIC AREAS: town centers, pedestrian areas, cycle lanes, car parking, concert and event venues…

- OTHER SECTORS: multistory and open-air car parking, regional airports, hospitals, exhibition centers, shopping centers, resorts, holiday villages, stadiums, sports centers, theme parks and recycling centers.

SURFACES

Concrete, porcelain tile, road surfaces, quartz finished concrete, paving stones, self-blocking paving stones, porphyry, sanpietrini (cobblestones), asphalt and any other floor types in any condition.

| TECHNICAL SPECIFICATIONS | HDK (diesel) |

|---|---|

| Cleaning path with two side brushes | 2.100 mm / 83 in |

| Cleaning path with side brush | 1.700 mm / 67 in |

| Cleaning path with main brush | 1.270 mm / 50 in |

| Dirt container capacity | 500 L /132 gal |

| High dump height | 1.580 mm / 62.2 in |

| Forward speed | 13,5 km/h / 8.4 mph |

| Hourly performance | 28.350 m²/h / 305,155 ft²/h |

| Filter type | Multipocket® / 13 m² / 140 ft² |

| Traction control | Hydraulic |

| Traction motor | Hydraulic |

| Diesel engine | Diesel Kubota, 1.500 cm3, a 4 cilindri / 36 hp |

| Weight (basic version) | 2.054 kg / 4,719 lbs |

| Dimensions – with side brushes (l x w x h) | 2.755 x 2.080 x 1.515 mm / 108.5 x 81.9 x 59.6 in |

| Dimensions – without side brushes (l x w x h) | 2.635 x 1.750 x 1.515 mm / 103.7 x 68.9 x 59.6 in |